As the welding industry advances, safety and environmental health continue to remain a top priority. Addressing day-to-day operational challenges, particularly related to welding fume and smoke, is essential. That's where FumeXtractors comes in – we have developed dynamic solutions to combat the welding fume issues faced by machine operators on a daily basis.

Our weld fume extraction systems are built to accommodate a diverse range of applications, including welding and plasma and laser cutting. They easily adapt to different machining processes, workspaces, and operational demands while maintaining a clean and safe working environment.

We are committed to delivering high-quality products that prioritize safety and help businesses comply with regulatory guidelines. Our product line, designed by industry experts, guarantees the protection of machine operators by effectively extracting harmful fumes and smoke, ensuring a healthy and clean air work environment.

Uncontrolled exposure to welding fumes and smoke poses severe health and safety risks. FumeXtractors offers adaptable solutions to eliminate these harmful air contaminants from the air stream. Our focus is on providing reliable, long-lasting solutions that ensure clean air and promote a healthier work environment.

FumeXtractors goes beyond simply offering fume extraction products; we provide comprehensive solutions. We work directly with engineers, distributors, and general contractors to provide turn-key prices and customized fume extraction systems. We are backed by a team with a combined experience of over 40+ years. Our dedication to excellence ensures that each of our systems is optimized for maximum effectiveness and efficiency.

From fume arms to downdraft tables, welding booths, and portables, our products are engineered to meet the highest quality standards and provide long-lasting performance. Customer satisfaction is our ultimate goal, and we go the extra mile to ensure that our solutions exceed your expectations.

Challenge:

Mission High School renovated a building on campus and needed to install welding booths and fume extraction systems in their welding workshop. They wanted to create an open aisle floor plan to facilitate easy monitoring of students' progress by the instructor.

Solution:

FumeXtractors provided the high school with welding booths and fume extraction equipment. We recommended fume extractors arms, which are designed to efficiently capture welding fumes and smoke at the source. Additionally, we supplied self-contained welding booths, enabling the instructor to change the configuration as needed.

Fume Extractor Arms

Fume extractor arms effectively capture fumes and smoke directly above the welding arc. Using a source capture method, fume arms efficiently remove harmful contaminants before they can enter the airstream. Our self-supportive arms provide flexibility without obstructing the view, allowing easy movement around projects.

Fume extraction arms come equipped with rotating flanged suction hoods to provide two times the suction distance. With various styles, arm lengths, hood diameters, mounting options, and lighting kits available, you can customize your fume arm solution by consulting with our specialists.

Our fume arms provide source capture in a variety of configurations:

✓ Hanging fume arms

✓ Standing fume arms

✓ Telescoping fume arms

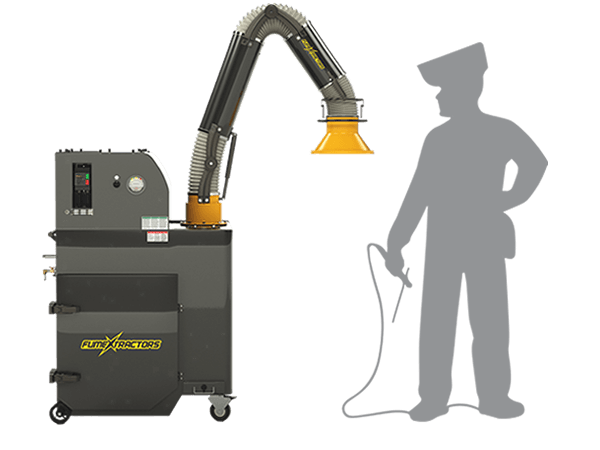

Portable Fume Extractors

Portable fume extractors use a source capture method to immediately remove welding fumes, smoke, and airborne contaminants before they reach breathing zones. Source capture draws air contaminants into the unit and through specialized filter media.

Portable systems feature a high-efficiency motor and a powerful aluminum propeller to maximize CFM at the extraction point.

Portables are an excellent solution for weld shops & offer various capacities:

✓ Production Grade Portables

✓ Medium Grade Portables

✓ Light Duty Portables

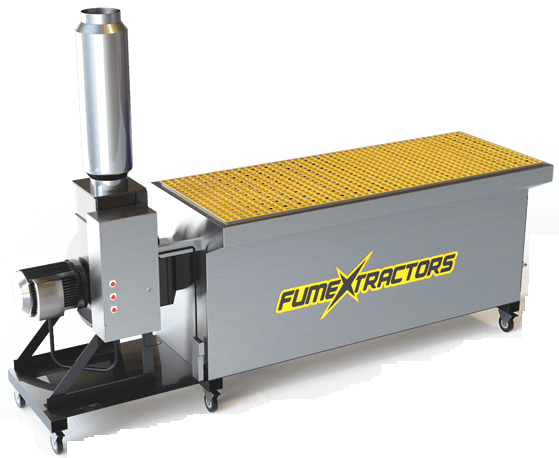

Downdraft Tables

Downdraft Tables offer a comprehensive solution for eliminating hazardous dust, smoke, and fumes at the source. These systems extract fumes and dust as they are generated, minimizing health and safety risks.

Our Dry and Wet Downdraft Tables provide superior safety by removing contaminants at a face velocity 2x higher than leading competitors. Designed for efficiency and ease of use, our downdraft tables are suitable for most demanding applications.

Downdraft tables benefit many applications & are available in a range of options:

✓ Dry downdraft tables

✓ Wet downdraft tables

Welding Booth

Welding booths are self-contained systems to ensure safety and efficiency with hands-free capture. Compatible with fume extraction arms, downdraft tables, and more, you can simply mount or place your extraction system inside the welding booth and connect it to a power source for immediate use.

FumeXtractors offers a comprehensive range of welding booths meeting OSHA and NFPA standards and available in standard sizes: 6' x 6' AWS and 5' x 5'.

Welding booths offer a range of benefits, including:

✓ 12ga double panel construction

✓ Fire resistant panels

✓ Easy installation

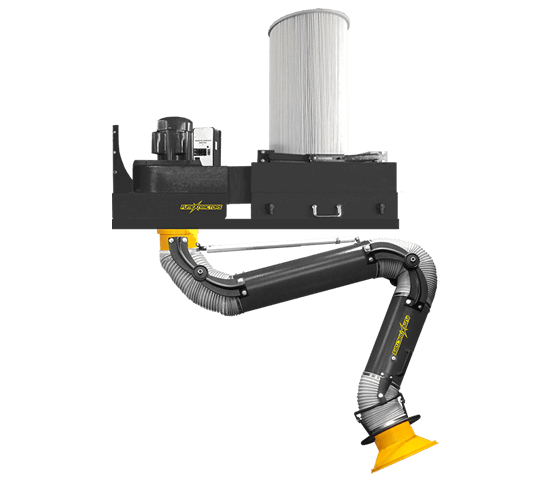

Wall Mount Fume Extractors

FumeXtractors offers Filtered Wall Mounted Fume Extractors for easy self-contained installation. Simply mount the unit to a wall or welding booth, connect to power, and start using it. These units include a spark trap for enhanced safety in spark-prone environments.

Our Ducted Wall Mount Fume Extractors are designed to exhaust fumes and dust either outside the facility or to a larger filtration system.

Wall mount fume extractors are made available in three different configurations:

✓ Filtration (pack & play)

✓ Filtration & Spark Trap

✓ Ducted (exhausts outside)

FumeXtractors solutions range everywhere from fume arms to downdraft tables to welding booths and portables. Our products are designed to deliver high-quality standards and long-lasting performance to ensure 100% customer satisfaction.

LEARN MORE ABOUT FUMEXTRACTORSCall Us Today -or- Request A Quote! Request a Quote